Story Highlight

– SMA, Aptamil, and Cow & Gate formulas recalled in UK.

– Contamination linked to cereulide toxin found in batches.

– 36 children showed symptoms of cereulide poisoning.

– Affected products can be returned for refunds or replacements.

– Safety gaps in baby formula regulation highlighted by experts.

Full Story

A significant recall of baby formula products has taken place across the UK, involving well-known brands such as SMA, Aptamil, and Cow & Gate. This action follows the discovery of traces of a harmful toxin, cereulide, in specific batches. As a precautionary measure, parents are being urged to examine their supplies at home to ensure the safety of their children.

The recall has been officially confirmed by the Food Standards Agency (FSA), which has actively expanded the list of affected products since the investigation began in early January. Currently, 28 different batches of infant formula have been recalled due to concerns regarding the potential contamination which could affect infants.

The first alert regarding the contamination arose from a single batch of Aptamil First Infant Formula earlier this year. Investigations have since revealed that the toxin’s presence is linked to a third-party supplier responsible for manufacturing arachidonic acid (ARA), a fatty acid that is often added to infant formulas. While ARA does occur naturally in breast milk, its addition to baby formula is not mandated by law.

Dr Chris van Tulleken, a noted physician and academic, provided insight into the matter on social media platform X, stating, “The contaminant seems to come from the fact that the ARA is produced using microbial fermentation—this process demands exceptionally tight manufacturing processes to ensure the right bugs grow the right stuff—and this has failed.” This indicates a potential lapse in the stringent quality control measures typically necessary in food production.

As health officials continue their investigations, 36 cases involving infants exhibiting symptoms consistent with cereulide poisoning have already been recorded in the UK. Cereulide is produced by Bacillus cereus, a bacterium that poses particular risks as its toxin cannot be eliminated through cooking or heat application, including when preparing infant formula according to NHS guidelines.

Parents should be attentive to a range of rapid-onset symptoms that can arise after consuming contaminated products. These symptoms encompass nausea, vomiting, diarrhoea, and abdominal cramps, often emerging within a timeframe of 15 minutes to six hours. Although healthy children might recover quickly once they cease consuming the affected formula, those who are particularly young or have weakened immune systems could face more serious health issues.

Katie Pettifer, Chief Executive of the FSA, reassured the public by stating, “The risk of harm to children from cereulide contamination at these levels is low, but consuming it could cause symptoms such as vomiting and diarrhoea.” She encouraged parents to consult their GP or contact NHS 111 if their child has ingested any of the recalled products and is exhibiting concerning symptoms.

In response to this alarming situation, the FSA is advising that all parents and caregivers check their stores for any baby formula from the specified brands and immediately discontinue use if the products are part of the recall. Families can return affected items to retailers for either a replacement or a full refund, eliminating the need for a purchase receipt.

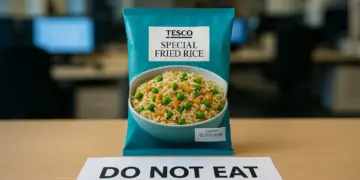

Both Danone and Nestle, the companies behind the affected brands, have announced that they will cease sourcing ingredients from the implicated supplier. Large supermarket chains, such as Tesco and Co-op, are reported to have unaffected formulations available for purchase, ensuring that parents can acquire safe products.

The implications of this recall have sparked a broader conversation regarding food safety regulations, particularly in relation to baby formulas. Experts in the field have voiced their concerns over apparent deficiencies in the current safety protocols and oversight mechanisms. Nigel Rollins, a professor of maternal and child health at Queen’s University Belfast, remarked on the situation’s gravity, calling it “extremely worrisome” and perceiving it as indicative of a “systematic failure in supply chain and food safety procedures and monitoring.”

In a similar vein, Patti Rundall, the policy director for Baby Milk Action and the International Baby Food Action Network (IBFAN) UK, expressed the urgent need for improved oversight. She noted, “When it’s your baby, you want to know that the systems are in place and that the frameworks are there, and they’re certainly not. When it’s reliant so much on trust and that companies will behave, I think we’re in a really bad place.”

In light of these developments, the FSA has confirmed that collaboration with international food safety authorities is ongoing, aimed at preventing such incidents in the future. Until clarifications regarding the situation are established, parents are advised to continue using unaffected products, ensuring their children’s safety remains the top priority.

Overall, the baby formula recall serves as a significant reminder of the crucial importance of rigorous monitoring and regulation in the food industry, particularly concerning products designed for vulnerable populations such as infants. Parents are encouraged to stay informed and proactive in safeguarding their children’s health in this challenging context.

Our Thoughts

The recall of SMA, Aptamil, and Cow & Gate infant formulas reveals significant lapses in food safety management. Key lessons include the necessity for stringent oversight of third-party ingredient suppliers. The contamination stemmed from the production of arachidonic acid (ARA) through microbial fermentation, which necessitates rigorous quality controls to prevent bacterial growth. Companies must prioritize adherence to the Food Safety Act 1990, which mandates that food businesses ensure the safety and suitability of food products.

Moreover, the failure to adequately monitor the supply chain highlights a breach of the General Food Law (EC) Regulation 178/2002, requiring traceability of food products. Companies like Nestlé and Danone should have implemented robust Hazard Analysis and Critical Control Points (HACCP) systems to identify and mitigate risks associated with their ingredients.

Preventative measures could include regular audits of suppliers, enhanced testing protocols for raw materials, and better traceability systems for batches of products. Additionally, consistent training and certification of staff handling food production are vital. Ultimately, compliance with food safety regulations and proactive risk management could significantly reduce the likelihood of similar incidents in the future.