Story Highlight

– Danone recalls 14 batches of baby formula due to contamination.

– Toxin cereulide may cause vomiting and stomach cramps.

– 36 UK children suspected of food poisoning already.

– Parents advised to check formula batches at home.

– Food safety investigations ongoing with international cooperation.

Full Story

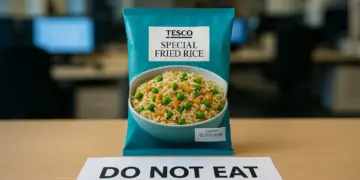

A recent recall of baby formula products in the UK has prompted food safety officials to urge parents to carefully review any formula they may have at home. The recall, initiated by Danone, impacts an additional 14 batches of Aptamil and Cow & Gate infant milks due to potential contamination with the toxin cereulide, which can pose health risks to infants.

Cereulide is known to cause symptoms such as vomiting and abdominal cramps. The Food Standards Agency (FSA) has reported that 36 children across the UK are currently suspected of suffering from food poisoning linked to these specific formula products. In light of this, parents and caregivers are advised to consult the FSA’s website for a detailed list of affected batches and to refrain from using any identified products.

Since December, several manufacturers, including Danone and Nestle, have executed recalls for infant formulas suspected of contamination, affecting over 60 countries globally. This situation includes recalls of products such as SMA, produced by Nestle, along with Aptamil and Cow & Gate, both manufactured by Danone. To date, a total of 28 formula batches have been recalled.

The FSA highlighted that traces of cereulide were discovered in a batch of Aptamil First Infant Formula in January, raising concerns about the safety of these products. Although both Danone and Nestle have assured the FSA that the contaminated batches were produced in the past and are unlikely to be found in retail stores, the concern remains that they could still be present in homes across the UK.

Cereulide is resilient and does not get neutralised by cooking or the preparation of infant milk. Consequently, consumption can lead to acute health problems. The FSA has linked this toxin to arachidonic acid (ARA) oil, an ingredient in infant formula designed to mimic some properties of breast milk. The agency confirmed that the contamination originated from a third-party supplier, which the companies are no longer sourcing materials from.

Katie Pettifer, Chief Executive of the FSA, commented on the situation, emphasising the responsibilities of food businesses. “Food businesses have a legal responsibility to sell safe food, including checking ingredients from suppliers are safe. We are working with international food safety authorities on this global recall and expect manufacturers to explain what went wrong and provide assurances this will not happen again,” she stated.

Danone North Europe has addressed the issue, expressing its commitment to stringent safety measures. A spokesperson for the company asserted, “We never compromise on food safety, and we want to reassure all parents that we take this responsibility seriously. All our baby formulas are produced under strict food safety and quality standards and undergo rigorous checks before leaving our factories.” They further mentioned that “low levels of cereulide” were previously detected in certain products, which have now been replaced.

As for consumers, major retailers including Tesco and Co-op are reported to still stock unaffected infant formula products, ensuring that parents can shop with confidence. “The affected batches are unlikely to still be on shop shelves but may be in your cupboard,” Pettifer reiterated. She urged consumers to return any recalled items to the store for an exchange.

Fortunately, UK health officials have indicated that none of the affected infants, who had consumed the problematic formula brands, have experienced serious health issues. The children impacted are believed to have consumed only the specific product batches implicated in the contamination.

Families concerned about this recall are encouraged to stay informed and take necessary precautions. Engaging with local health services and monitoring updates from the FSA can help parents navigate this troubling situation effectively.

The broader implications of this incident raise questions about food safety protocols and the rigorousness of supply chain management practices among baby formula manufacturers. The FSA’s commitment to collaborating with food safety authorities internationally aims to enhance accountability and improve future food safety measures.

In conclusion, the recent alert surrounding baby formula products serves as a significant reminder of the necessity for thorough oversight and transparency in food manufacturing. Parents are advised to exercise vigilance while monitoring their supplies and remain proactive in safeguarding their children’s health by adhering to guidance from health authorities.

Our Thoughts

To mitigate the recent contamination incident involving baby formula, several key safety lessons can be learned. Firstly, a more robust risk assessment process should have been implemented by manufacturers, focusing on supplier quality control. The Food Safety Act 1990 mandates that food businesses ensure the safety and suitability of food, including verifying the safety of ingredients from third-party suppliers. The contamination source, identified as ARA oil from a third-party supplier, indicates a failure to effectively vet suppliers under the relevant regulations.

Moreover, stricter adherence to Hazard Analysis and Critical Control Points (HACCP) principles could have prevented the issue. Companies are required to have effective procedures in place to prevent food safety hazards. Regular and thorough inspections of supplier practices could ensure ongoing compliance with UK regulations, such as the General Food Law Regulation (EC Regulation 178/2002).

In the future, increased transparency in the supply chain and consumer communication is essential. Prompt public notifications and educational campaigns about checking for recalls can further protect consumers. Lastly, regular audits of all suppliers and ingredient testing could significantly reduce the risk of similar incidents occurring.