Story Highlight

– Employee injured while cleaning a running horizontal borer.

– Company lacked proper machine guarding and safe work systems.

– Employee suffered severe injuries, including broken ribs and amputation.

– Site and Field Services Limited fined £40,000 for violations.

– HSE emphasizes importance of effective safety monitoring and audits.

Full Story

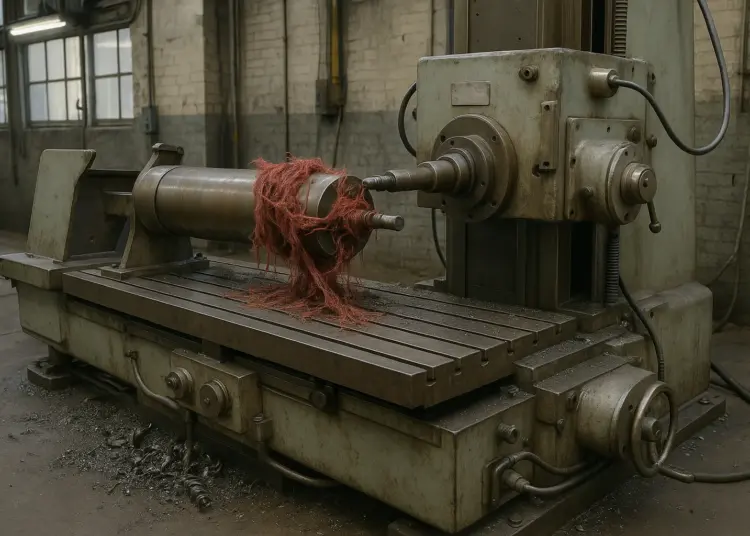

A health and safety violation has led to significant legal repercussions for a Northumberland company after an employee suffered severe injuries while undertaking maintenance work. The incident occurred on 30 November 2023, as the worker was engaged in cleaning operations on a horizontal borer machine. While performing these tasks, the employee became caught in the machine’s rotating tool, which was still operational at the time.

This unsettling incident has drawn scrutiny from the Health and Safety Executive (HSE), which serves as the principal authority on workplace health and safety standards in the UK. Subsequent investigations revealed that Site and Field Services Limited, based in Freeman Way on the North Seaton Industrial Estate in Ashington, failed to implement necessary safety measures concerning the machinery. It was discovered that the company did not have appropriate guards in place to prevent access to moving parts and had not established a safe system of work for using the machine effectively.

Moreover, the HSE’s inquiry flagged particular deficiencies in the company’s daily safety practices. Routine auditing of daily check sheets was inadequate, resulting in a critical failure to notice the absence of a trip probe meant to halt the machine’s operation during unsafe conditions. These oversights culminated in a serious workplace accident that led to the employee suffering extensive injuries, including multiple rib fractures, significant damage to both legs and ankles, a collapsed lung on the left side, and the necessity for skin grafts along with the partial amputation of two toes.

The incident marked a continuation of safety concerns at the facility, where prior inspections by HSE had already identified issues related to machine guarding that demanded rectification. Following the court proceedings, Site and Field Services Limited was found guilty of contravening Section 2(1) of the Health and Safety at Work etc. Act 1974, a regulation that mandates employers to take all reasonably practicable steps to ensure the health and safety of their employees. The court imposed a fine of £40,000 on the company and required it to pay an additional £6,382 in associated costs.

Darian Dundas, an inspector with the HSE, emphasised the critical importance of ongoing evaluation and inspection of safety measures: “Effective monitoring, auditing and review of guarding is essential to demonstrate that it is effective in controlling risk.” This statement underscores the necessity for businesses to prioritise robust safety protocols to prevent workplace accidents.

The prosecution was conducted by HSE enforcement lawyer Arfaq Nabi, with the support of Paralegal Officer Stephen Grabe, highlighting the collaborative efforts within the regulatory body to enforce compliance with health and safety legislation.

This incident serves as a stark reminder of the potential dangers present in industrial environments, particularly where heavy machinery is involved. The catastrophic consequences of neglecting proper safety practices can have far-reaching impacts not only on the injured employee but also on their family and the wider community.

Site and Field Services Limited’s failure to act is indicative of a broader challenge faced by many employers in reconciling operational efficiency with safety standards. Experts in occupational health and safety advocate for a comprehensive approach that includes regular training for employees, thorough risk assessments, and a culture that promotes open communication about safety concerns.

As the company moves forward, it will be essential for it to reassess its safety systems and implement the necessary changes to safeguard its workforce. The HSE continues to provide guidance and resources to improve workplace conditions across sectors, reinforcing the commitment to ensuring that such incidents do not repeat in the future.

For more insights into health and safety regulations and the responsibilities of employers, the HSE offers extensive resources and updates that can aid companies in maintaining compliance and protecting their employees.

This incident is a stark reminder that equipment should never be cleaned or serviced while still running and that machine guarding and clear safe working procedures are non negotiable. Management must ensure thorough risk assessments, provide adequate training and supervision, and carry out regular checks to make sure controls remain effective. Employers have a duty to prevent foreseeable harm and investing in proper safety measures is far cheaper than the human and financial cost of an avoidable injury.

This is a stark reminder that machine guarding and safe working procedures are not optional. Employers must assess risks, provide effective guards, lockout procedures and training, and ensure supervisors actively monitor compliance. Investing in these measures protects workers from life changing injuries and avoids significant financial and reputational consequences for the business.

This incident is a clear reminder that machinery must never be cleaned or maintained while it is running and that adequate guarding and formal safe systems of work are essential. Employers must assess risks, ensure isolation procedures are in place and followed, provide training and supervision, and carry out regular monitoring and maintenance so workers are not exposed to preventable hazards. The consequences for the injured employee and the company underline why safety needs to be actively managed and continuously reviewed.

This incident is a stark reminder that machinery risk must be controlled before work starts. Routine cleaning or maintenance on running equipment is not an acceptable shortcut. Employers must fit appropriate guards, establish safe systems of work and ensure all staff are trained and supervised so risks are eliminated or reduced. Regular inspections and active monitoring of safety controls would have prevented this harm. Prioritising safety saves people from life changing injuries and avoids serious financial and reputational consequences.