Story Highlight

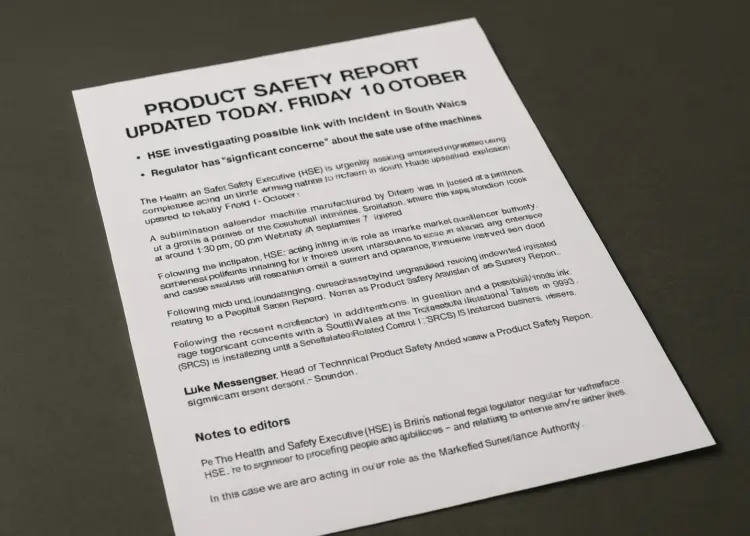

– HSE updates Product Safety report regarding printing machinery.

– Explosive incident occurred in Swindon, no injuries reported.

– HSE warns users to follow safety guidance immediately.

– Investigation into machine design linked to South Wales explosion.

– Revised guidance includes mandatory safety system installation.

Full Story

The Health and Safety Executive (HSE) has issued a renewed call for vigilance from businesses using certain types of printing machinery, particularly following a recent explosion in Swindon. This guidance, having been updated today, 10 October 2025, stems from rising concerns regarding the safety of sublimation calender machines, one of which was involved in the incident on 24 September at a printing facility located within the Groundwell Industrial Estate.

Fortunately, this explosion, which occurred around 7.30pm, did not result in any injuries. However, the HSE has underlined the importance of adhering to established safety protocols. In light of the incident, the regulator has proactively reached out to current users of similar machinery, urging them to consult the guidance originally published last year. The advice stresses the need for immediate compliance and cautions businesses to halt operations if there is any uncertainty about the machinery’s safety.

The explosion in Swindon is particularly alarming as it correlates with an ongoing investigation concerning a similar incident that took place in 2023 at the Treforest Industrial Estate in Rhondda Cynon Taff, South Wales. Tragically, that event resulted in the death of a director from a nearby food laboratory. Following that prior explosion, the HSE collaborated with the Office for Product Safety Standards (OPSS) to issue a critical Product Safety Report detailing necessary precautions and recommended practices for operating such machinery.

In their latest assessment, the HSE has reinforced key aspects of this safety guidance, which now includes a strong recommendation that the machinery should never be left unattended while connected to a power source. Additionally, businesses are advised to suspend the use of these machines until a second independent Safety-Related Control System (SRCS) has been installed and verified by a qualified professional.

Luke Messenger, who serves as the Head of Technical Product Safety at HSE, expressed serious concerns regarding the safe operation of these machines. He stated, “We have significant concerns about the safe use of these machines. The guidance issued following the Treforest Industrial Estate incident has clear instructions – revisions to this have been published today, and we will continue to share any further updates. We never want to see a repeat of the fatality in 2023 or the recent catastrophic explosion in Swindon.”

The HSE’s approach includes extensive outreach to companies that may be operating the potentially hazardous machines. They are working to identify and contact all users and are collaborating with UK border officials to prevent any further importation of Diferro machines, the brand implicated in the latest incident and the prior explosion in South Wales.

As the investigation into the Swindon explosion unfolds, the Health and Safety Executive has indicated that a decision regarding whether to pursue a formal investigation into this event will be determined according to their established criteria for incident selection. The authority is currently prioritising the examination of the 2023 Treforest incident, where it has now assumed primary responsibility for the investigation.

This development comes as the HSE continues to play a critical role in maintaining workplace safety standards in what is regarded as a high-risk environment. The overarching mission of the HSE is to protect individuals and spaces in the workplace to foster safer and healthier working conditions.

The updated Product Safety Report, initially released in April 2024, reflects the HSE’s commitment to continuous improvement in safety regulation, particularly concerning the machinery that poses a risk to personnel. Stakeholders in the printing industry and beyond are advised to remain vigilant and proactive in adhering to the recommendations set forth by the HSE to prevent future incidents.

This is a stark reminder that complacency around machinery safety can have catastrophic consequences. Operators and owners must act now to review risk assessments, ensure maintenance and inspection regimes are up to date, and fit a second independent safety related control system where required. Training and supervision must be effective so staff recognise hazards and follow procedures. Regulators and duty holders should share lessons from these incidents to prevent further harm.

This is a timely reminder that complacency around machinery safety can have catastrophic consequences. Employers should immediately review their risk assessments and machine safety systems, ensure second independent safety related controls are fitted where required, check maintenance and inspection records, and verify staff are trained and competent to operate and maintain calender and other printing equipment. Regulators and businesses must treat the HSE guidance as mandatory best practice and act without delay to protect workers and prevent further incidents.

This is a stark reminder that complacency has no place in machinery safety. Even when incidents do not cause injuries, they reveal failures in controls or maintenance that could lead to tragedy. Operators must review their risk assessments, ensure all safety related control systems are independent and redundant, and verify that procedures for inspection, cleaning and safe working are followed and documented. Suppliers and maintenance contractors should confirm conformity with current guidance and provide clear evidence of functional safety measures. Regulators and duty holders need to treat these reports as urgent prompts for action rather than distant warnings.

This is a stark reminder that complacency around machinery safety can have fatal consequences. Owners and managers must act now to review risk assessments, verify that safety related control systems are independent and fail safe, and ensure staff receive practical training on safe operation and emergency procedures. If a second independent control system is not in place, stop using the equipment until the necessary modifications and independent verification are completed. Record all inspections and tests, report defects immediately, and engage a competent person or the HSE for advice if unsure.