Story Highlight

– Worker suffered burns from corrosive drain unblocker.

– Incident occurred during decanting operations at Flowchem UK.

– Inadequate training and PPE contributed to safety risks.

– Flowchem fined £50,000 for health and safety breaches.

– Changes made to working methods post-incident for safety.

Full Story

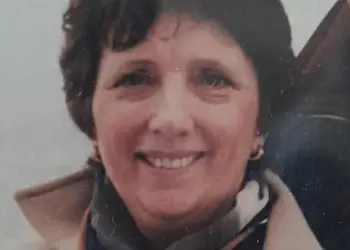

An agency worker at Flowchem UK, located in Sandiacre near Nottingham, experienced severe injuries after being exposed to a hazardous chemical during her employment. Marzanna Sokolowska, who was involved in transferring a corrosive sink and drain unblocker from large containers into smaller ones, sustained burns to her face, eye, neck, and arm as a result of an unfortunate accident that occurred on November 2, 2023.

While working in a team responsible for this liquid decanting process, Ms Sokolowska inadvertently activated the outlet valve of a nearby container. The absence of an end cap on this container caused the unblocker to spray out forcefully, dousing her in the harmful substance. The injuries she suffered were reported as “very painful,” resulting in her being unable to work for an extended period.

An investigation conducted by the Health and Safety Executive (HSE) following the incident highlighted numerous health and safety failings at Flowchem. These issues included not only the risks associated with potential leaks but also the inadequate training provided to employees, particularly those with limited English proficiency. Although some personal protective equipment (PPE) was made available, it was often not worn properly, and oversight regarding the use of such equipment was found to be lacking. Furthermore, while eye-wash bottles were present, the facility’s first aid provisions failed to address the possibility of extensive chemical exposure; for instance, there was no safety shower available for emergencies.

On February 12 of this year, at Nottingham Magistrates’ Court, Flowchem UK entered a guilty plea to multiple violations of the Health and Safety at Work Act. Consequently, the company was fined £50,000 and ordered to pay additional costs of £7,247.40, alongside a victim surcharge amounting to £2,000.

HSE guidelines related to the Control of Substances Hazardous to Health Regulations (COSHH) stipulate that it is essential for employers to recognise the dangers posed by hazardous substances and implement effective measures aimed at preventing exposures and addressing the repercussions of any accidents. These measures should encompass the evaluation of work systems for handling dangerous substances, the training and supervision of staff, and the provision of appropriate PPE and first aid facilities.

Angus Robbins, an HSE inspector involved in the case, expressed concerns regarding the safety practices at Flowchem, stating: “The systems of work employed by Flowchem unnecessarily exposed workers to risks of injury from exposure to corrosive chemicals.” He further noted that alternative working methods could have been employed to mitigate such risks, such as avoiding the decanting of large volumes of chemicals stored at or above head height.

In the aftermath of the incident, Flowchem reassessed and modified its working practices to eradicate the identified hazards. Although Ms Sokolowska endured significant and painful injuries, particularly on her eyelid, she has since made a commendable recovery and is back at work.

Flowchem UK, situated on Mark Street, has yet to comment on the incident, according to inquiries from Nottinghamshire Live.

The case underscores the critical need for stringent safety measures in environments where hazardous substances are present. The HSE continues to advocate for the implementation of comprehensive risk assessments and effective training programs to ensure worker safety. This incident has prompted discussions on the importance of providing adequate resources and protocols to protect employees from chemical hazards.

Safety experts have frequently highlighted the dangers associated with the improper handling of corrosive substances. Recent events serve as a reminder not only of the potential for severe injury but also of the responsibilities that employers have towards their workers. It is vital that companies ensure their staff are equipped with the necessary tools and knowledge to carry out their duties safely.

The injuries sustained by Ms Sokolowska reflect the potential consequences of negligence in health and safety compliance. Efforts must continually be made to foster a safety-first culture within workplaces, particularly in industries handling dangerous materials. Only through rigorous adherence to established guidelines and proactive management of health and safety protocols can such incidents be prevented in the future.

While Flowchem UK has taken steps to improve its processes following this incident, the case remains a pertinent example for other businesses about the need for diligent attention to health and safety regulations. The balance between operational efficiency and employee safety must always be prioritised, ensuring that workers are never placed in harm’s way.

Our Thoughts

The incident involving Marzanna Sokolowska at Flowchem UK highlights several critical failures in health and safety practices. To prevent such accidents, a thorough risk assessment should have been conducted in line with the Health and Safety at Work Act 1974 and the Control of Substances Hazardous to Health Regulations (COSHH) 2002. Specifically, the company should have implemented safer decanting procedures, avoiding the handling of hazardous chemicals at shoulder height, and ensuring that outlet valves had appropriate end caps to prevent accidental release.

Additionally, inadequate training and communication, particularly for workers with limited English proficiency, should have been addressed. Comprehensive training programs that ensure understanding of safety protocols and proper equipment usage are essential.

The provision and consistent use of personal protective equipment (PPE) need to be monitored closely, along with robust first aid provisions, including emergency showers for chemical exposure. Ultimately, Flowchem’s systems of work lacked adequate safety measures, reflecting a breach of relevant regulations, which could have mitigated both the exposure risks and the severity of the injuries sustained.