Story Highlight

– Worker died after hydrogen sulphide exposure at Futamura.

– Delivery driver collapsed while attempting rescue.

– Futamura fined £200,000 for health safety breaches.

– Inadequate risk assessment identified for drainage system.

– Company expressed condolences for employee’s death.

Full Story

A packaging film manufacturer has been fined over £200,000 following a tragic incident involving the death of a worker who was exposed to toxic hydrogen sulphide gas. The incident, which occurred at the Futamura Chemical facility located in Wigton, Cumbria, has raised concerns regarding workplace safety and the adequacy of the safety measures in place.

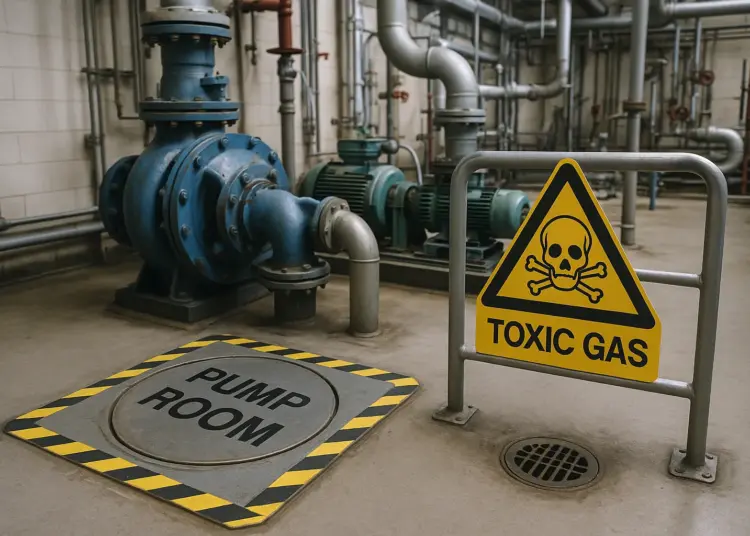

The incident took place on Christmas Eve, 24 December 2021, when Alexander Cole, who was affectionately known as Alec, was discovered unconscious in a pump room at the plant. The 35-year-old employee had been exposed to hydrogen sulphide, a potentially lethal gas. Robert Dyer, a delivery driver who arrived at the scene to assist the stricken Cole, was himself overcome by the same toxic gas. Both men were subsequently rescued, but unfortunately, Cole succumbed to his condition the following day while receiving treatment in hospital.

An inquest into Cole’s death determined that hydrogen sulphide played a significant role in the circumstances surrounding his demise. According to the Health and Safety Executive (HSE), their investigation revealed that while Futamura Chemical UK Limited had conducted a risk assessment concerning hydrogen sulphide in the production area and implemented certain control measures, there were critical oversights. Specifically, the safety assessment failed to adequately address the potential for the gas to accumulate within the drainage system at the site.

During a court hearing on 6 January at Warrington Magistrates’ Court, Futamura Chemical UK pleaded guilty to violating regulations under the Health and Safety at Work etc. Act 1974. The court imposed a fine of £200,000 and ordered the company to pay an additional £20,000 towards costs associated with the investigation.

HSE inspector Matthew Shepherd highlighted the gravity of the situation, stating that the case underscores the necessity for comprehensive risk assessments in workplaces where hazardous substances are present. He emphasised the need for companies to meticulously evaluate and control all possible exposure pathways, warning that neglecting such responsibilities can lead to dire consequences.

In response to the incident, Futamura expressed profound sorrow over Cole’s passing, describing him as a valued and respected member of the team. The company reiterated its sympathies to Cole’s family and friends, remarking on the significant impact his death has had on both the organization’s directors and employees. Futamura acknowledged their guilty pleas to two charges concerning failures to safeguard both an employee and a contractor to the extent that was reasonably practicable.

The presiding judge noted Futamura’s cooperation with the HSE throughout the investigation process. The company reaffirmed that maintaining the highest health and safety standards is a priority that underpins its operations and business principles.

Hydrogen sulphide, which has a characteristic smell akin to rotten eggs, poses serious health risks. Symptoms following inhalation of high concentrations can include sudden loss of consciousness and respiratory failure, often leading to fatal outcomes within minutes. The gas can occur naturally but is also released during various industrial processes, including wood pulp production, which is fundamental to Futamura’s operations.

Following the court’s verdict, an HSE lawyer involved in the prosecution, stated that the incident reflects broader safety challenges within the industry, emphasising the vital importance of effective monitoring and control measures for hazardous substances in the workplace. The HSE continues to provide resources and guidance regarding the safe handling of hazardous materials, which can be accessed on their website.

This distressing incident serves as a reminder of the significant responsibilities employers hold in ensuring a safe working environment. It emphasizes that safety precautions must extend beyond immediate operational areas to encompass all potential hazards, particularly in environments where harmful gases are present. The hope is that lessons learned from this tragedy will lead to improved practices and a renewed focus on health and safety protocols across the packaging and manufacturing sectors.

Our Thoughts

The tragic incident at Futamura Chemical highlights critical failures in risk management related to hazardous substances, specifically hydrogen sulphide. While a risk assessment was conducted for the production area, it inadequately addressed the risks associated with potential gas build-up in the drainage system. To prevent such incidents, a more comprehensive risk assessment should have been performed, taking into consideration all possible exposure pathways, especially in confined or poorly ventilated areas.

Key safety lessons include the importance of thorough evaluation and monitoring of the work environment regarding toxic gas emissions and ensuring that all employees are trained in emergency response procedures. The Health and Safety at Work etc. Act 1974, particularly Sections 2(1) and 3(1), was breached as the employer failed to adequately protect both employees and contractors.

To avoid similar incidents, organizations must implement robust controls under the Control of Substances Hazardous to Health (COSHH) Regulations, continuously monitor air quality, and enhance training on recognizing and responding to hazardous situations. Regular review and improvement of safety protocols related to toxic substances are essential in safeguarding worker health.