Story Highlight

– Disaronno liqueur recalled due to glass fragments risk.

– Affected bottles are 700ml with specific batch codes.

– Consumers advised not to consume and return bottles.

– Major retailers instructed to display return notices.

– Manufacturer emphasizes consumer safety and quick action.

Full Story

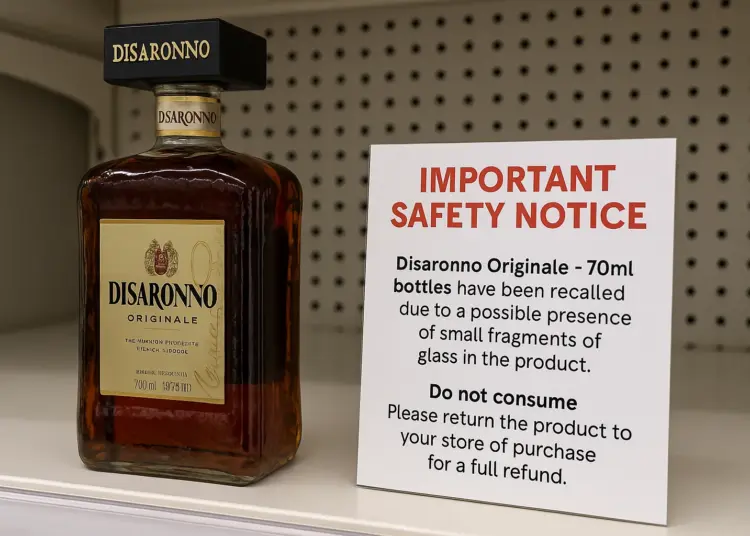

A significant recall has been initiated for one of the UK’s favourite festive liqueurs, Disaronno Originale, due to concerns about potential glass contamination. This almond-flavoured spirit, a staple choice for many during Christmas celebrations, is being withdrawn from store shelves following warnings from the Food Standards Agency (FSA).

On Tuesday, 9 December 2025, the FSA announced the urgent recall after Illva Saronno S.p.A., the manufacturer, identified a defect in the production process. This flaw may have resulted in the introduction of tiny glass particles into a limited selection of 700ml bottles of Disaronno. The recall affects various regions, including England, Scotland, and subsequently, the Republic of Ireland.

With the festive season in full swing, when demand for festive liqueurs tends to spike due to their popularity as gifts and during gatherings, the discovery of potential contamination has led to immediate action from retailers and health authorities alike.

**Identification of Affected Products**

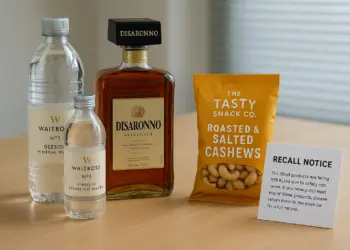

Only specific 700ml bottles of Disaronno Originale are included in this recall. Consumers are urged to check the batch code located on the label of their bottles, ensuring they compare it against the list provided by the authorities. Importantly, other sizes or varieties of Disaronno are unaffected, which helps narrow down the potential risk.

In relation to this situation, the Republic of Ireland’s Food Safety Authority (FSAI) has issued separate alerts concerning different batches. However, the FSA’s alert in the UK specifically pertains to seven designated batch codes: 25374, 25375, 25381, 25382, 25435, 25442, and 25444.

Illva Saronno S.p.A. has highlighted that the contamination resulted from an “anomaly on a bottling line,” leading to the possible inclusion of foreign bodies, namely micro-glass fragments, in certain bottles. This incident underscores the careful protocols required in the manufacturing process for consumables, particularly during peak sales periods.

**Immediate Consumer Guidance**

The FSA, in collaboration with the manufacturer, has prioritised consumer safety, urging anyone who has purchased the affected bottles not to consume the product. Instead, they are advised to return the items to the place of purchase for a full refund or replacement.

This swift action reflects the serious nature of the risks associated with glass fragments in food and drink products, and the urgency with which the situation has been addressed. Despite the fact that the contamination is limited to specific batches, the festive retail environment—characterised by increased sales of alcoholic beverages—raises concerns that these potentially harmful products could be widespread in households.

The manufacturer has also expressed regret over the inconvenience caused, reiterating its commitment to prioritising consumer well-being during this incident.

**Next Steps for Consumers in the UK**

For individuals who have purchased the 700ml bottle of Disaronno Originale, the immediate course of action is to check the batch code thoroughly. This can be done easily by inspecting the label on the bottle to see if it matches any of the aforementioned codes associated with the recall.

Customers do not need to present a receipt when returning the contaminated product. The return process is designed to be as hassle-free as possible: consumers should return the bottle to the store from where it was bought, whether it be a large supermarket chain or a local retailer, to receive either a full refund or a safe replacement.

This straightforward procedure aims to facilitate the recovery of impacted bottles and minimise any public health risks promptly, especially as the Christmas season, when such liqueurs are a common purchase, is now underway. For additional information, consumers can directly contact Illva Saronno S.p.A. through their customer service channels.

**Context and Industry Implications**

Recalls related to glass contamination, while uncommon, do occur in the beverages sector and are often linked to issues with bottling technology or the glass manufacturing supply chain. There have been previous cases where well-known beverage brands, ranging from beers to whiskies, have had to manage similar recalls due to the potential presence of glass fragments.

The incident involving Disaronno serves as a pertinent reminder of the vulnerabilities inherent in large-scale food and drink production processes, even for globally recognised brands. It underscores the critical responsibility of regulatory bodies like the FSA, along with national equivalents in other regions such as the FSAI in Ireland, to act swiftly to safeguard consumer health.

**Conclusion**

The recall of Disaronno Originale highlights the necessity of vigilance when it comes to consumer safety, even within reputable brands. As millions of consumers prepare for holiday festivities, the rapid and effective response from the FSA ensures that products posing a risk are swiftly identified and eliminated from circulation.

For the public, the essential takeaway is clear: check your bottles, follow guidance on returns, and refrain from consumption of affected products. During this bustling season, continuous vigilance, along with cooperation and communication from retailers and health authorities, remains crucial to ensuring the safety of households across the UK.

Our Thoughts

The Disaronno Originale recall highlights several key safety lessons and potential regulatory breaches. To prevent such incidents, the manufacturer, Illva Saronno S.p.A., should have implemented more rigorous quality control measures during the bottling process to detect and eliminate risks of contamination, aligning with the requirements of the Food Safety Act 1990. Regular audits and maintenance of bottling lines could have identified the anomaly before reaching consumers.

The swift action taken by the Food Standards Agency (FSA) demonstrates adherence to the principles of the General Food Law Regulation (EC) 178/2002, emphasizing food safety and consumer protection. However, the initial failure in the manufacturing process represents a breach of due diligence in maintaining product safety.

To prevent similar incidents, the implementation of a robust Hazard Analysis and Critical Control Point (HACCP) system is essential, ensuring critical points in the production process are monitored and controlled effectively. Furthermore, enhancing transparency and communication with consumers regarding product safety can foster trust and safeguard public health, especially during high consumption periods like the festive season.