Story Highlight

– Futamura fined £200,000 for hydrogen sulphide exposure.

– Employee Alexander Cole collapsed due to gas exposure.

– Delivery driver Robert Dyer also affected, but recovered.

– Cole died in hospital; gas exposure contributed to death.

– Company failed to adequately assess risk of gas buildup.

Full Story

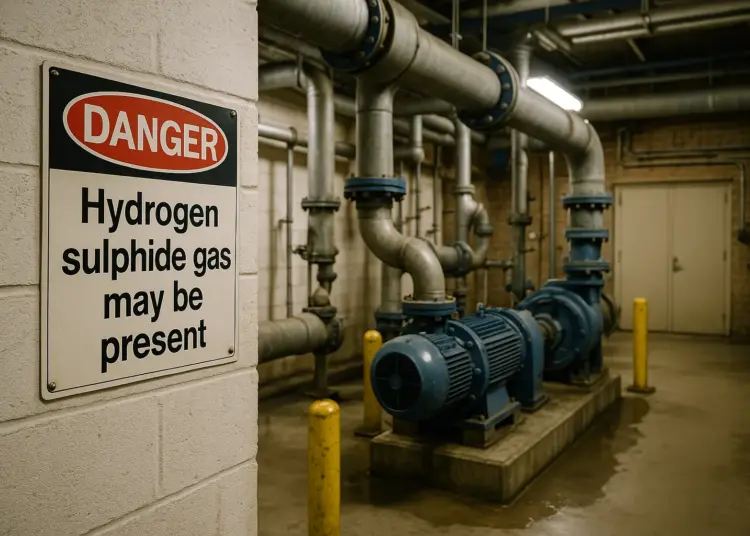

Futamura Chemical UK Ltd, a manufacturer of cellulose film packaging, has been fined £200,000 after a tragic incident involving hydrogen sulphide gas led to the death of an employee. The case sheds light on the critical need for rigorous health and safety measures in workplaces dealing with hazardous materials.

The incident occurred on December 24, 2021, at Futamura’s facility in Wigton, Cumbria. Alexander Cole, known to colleagues as Alec, collapsed in a pump room due to exposure to toxic hydrogen sulphide. In a courageous attempt to assist him, delivery driver Robert Dyer also succumbed to the gas and lost consciousness. Fortunately, both men were rescued from the pump room, with Mr Dyer regaining consciousness shortly thereafter. However, Mr Cole was taken to the hospital, where he passed away on Christmas Day, a loss mourned deeply by his family and colleagues.

A subsequent inquest determined that hydrogen sulphide gas was a contributing factor in Mr Cole’s untimely death. This incident prompted an investigation by the Health and Safety Executive (HSE), which revealed significant shortcomings in Futamura’s risk management practices. It was found that the company had not sufficiently assessed the risks associated with their production process, particularly regarding the presence of hydrogen sulphide as a by-product.

While Futamura had conducted a risk assessment concerning hydrogen sulphide within the production area, it failed to adequately evaluate the associated risks linked to the gas potentially accumulating within the site’s drainage system. This oversight meant that hydrogen sulphide could inadvertently escape from the drains, thereby endangering workers on-site.

Described as a colourless gas with a distinctive odour reminiscent of rotten eggs, hydrogen sulphide is recognised as being detrimental to health. Exposure to this gas can lead to a range of health issues, including dizziness, loss of consciousness, irritation of the eyes, and in severe cases, fatality—depending on factors such as the concentration of the gas and duration of exposure.

According to HSE guidance, it is an employer’s responsibility to conduct thorough risk assessments and take appropriate measures to minimise exposure to harmful substances. The HSE’s Control of Substances Hazardous to Health (COSHH) guidelines provide further detail on the responsibilities of employers in managing hazardous materials within the workplace.

On January 6, at Warrington Magistrates’ Court, Futamura Chemical (UK) Ltd pleaded guilty to violations of Sections 2(1) and 3(1) of the Health and Safety at Work etc. Act 1974. The court’s ruling included the imposition of a £200,000 fine, along with an additional £20,000 in costs.

Following the court proceedings, HSE Inspector Matthew Shepherd highlighted the crucial nature of comprehensive risk assessments. He remarked, “This tragic case shows the importance of conducting a thorough and robust risk assessment to ensure that all risks are properly identified and managed. Where companies use, or produce within their processes, substances harmful to health, it is vital that they have fully considered and controlled all pathways to exposure. Failure to do so can have terrible consequences.”

The prosecution was carried out by HSE enforcement lawyer Karen Park and paralegal officer Benjamin Stobbart, underscoring the HSE’s commitment to safeguarding worker safety through stringent legal enforcement.

In light of these events, a spokesperson for Futamura expressed profound sadness over Mr Cole’s death, underscoring the emotional impact on the company and its employees. The statement read: “Futamura was deeply saddened by the death of Alexander Cole, whom we knew as Alec. Alec was a well-liked, respected and long-serving member of our close-knit team, and his death has had a profound effect on both the directors and staff of the company. The company wishes to express once more its sympathies to Alec’s family and friends.”

The spokesperson further confirmed that understanding and maintaining the highest standards of health and safety management is critical to the company’s operations. They acknowledged the support Futamura provided during the HSE investigation, indicating a commitment to preventing similar incidents in the future.

While the fine serves as a stern reminder of the responsibilities that companies carry in ensuring the health and safety of their employees, the true impact of such tragedies resonates far beyond financial penalties. The loss of a colleague not only affects immediate family and friends but also ripples through the entire workplace community, emphasising the human cost of unsafe working conditions.

As industries continue to navigate the complexities of workplace safety, the necessity for robust health and safety practices cannot be overstated. Employers are urged to reassess their systems regularly, ensure adequate training for staff, and maintain an open dialogue about safety in order to foster a culture of health and protection at work.

As the fallout from this incident reverberates through Futamura and the broader sector, it also serves as a clarion call for businesses to elevate their commitment to workplace safety, ensuring that no worker’s life is put at risk due to negligence or insufficient safety measures. The tragic death of Alexander Cole stands as a stark reminder of the paramount importance of employee safety in every aspect of business practice.

Our Thoughts

Futamura Chemical UK Ltd could have prevented this tragic incident by conducting a more comprehensive risk assessment that included potential hydrogen sulphide build-up in the drainage system, as required under the Control of Substances Hazardous to Health (COSHH) Regulations. The company failed to identify the risk posed by the gas being released from the drains, despite having implemented some control measures for its presence in the production area.

Key safety lessons include the necessity of evaluating all possible pathways for exposure to harmful substances and ensuring that appropriate risk controls are implemented across all areas of operation. Adequate training for employees and regular safety audits could further mitigate risks associated with hazardous substances.

The breaches of the Health and Safety at Work etc. Act 1974, specifically Section 2(1) (failure to ensure the health, safety, and welfare at work of employees) and Section 3(1) (failure to ensure, as far as is reasonably practicable, the health and safety of non-employees), highlight significant lapses in safety management. Similar incidents can be prevented by robust risk assessment processes and a comprehensive safety culture that prioritizes employee wellbeing.