Story Highlight

– Worker had leg amputated; significant injuries to other leg.

– E.T.C. Sawmills fined £160,000 for safety violations.

– Major injury rate in sawmilling is significantly higher.

– HSE guidance available for safer sawmilling practices.

– Lack of risk assessment led to life-changing injuries.

Full Story

A Shropshire wood manufacturing firm has been penalised with a substantial fine following a severe workplace accident that resulted in life-altering injuries to an employee. E.T.C. Sawmills Limited faced the financial repercussions amounting to £160,000 as issued by Kidderminster Magistrates’ Court due to unsafe working conditions that led to the incident involving Robert Stubbs, a 37-year-old worker.

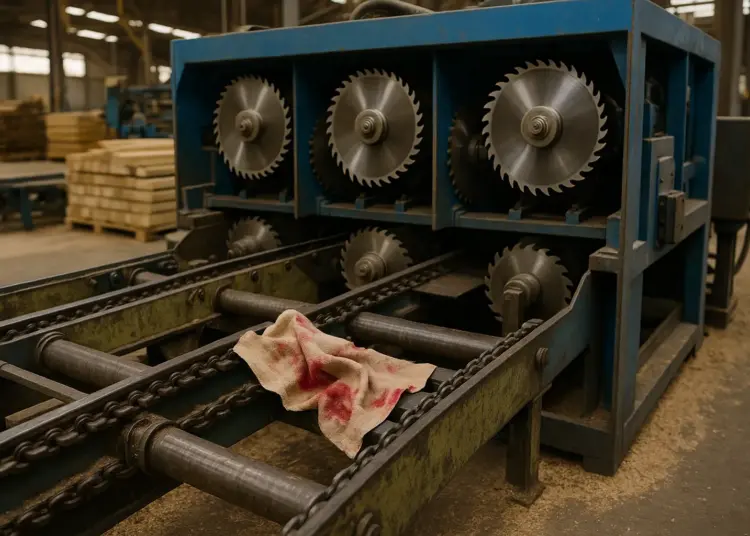

The incident occurred in May 2021 at the company’s facility in Ellesmere, where Mr Stubbs was tasked with clearing a jammed log while operating machinery. While attempting to rectify the problem, Mr Stubbs ascended onto a stationary conveyor bed and utilised a metal pole to manoeuvre the obstructing log. However, the conveyor belt unexpectedly resumed movement, ensnaring his legs and subjecting them to significant injury as they became trapped against a stop plate. This resulted in the amputation of his right leg below the knee and caused serious damage to his left leg.

Following an exhaustive investigation by the Health and Safety Executive (HSE), it was determined that E.T.C. Sawmills had failed in its legal obligations to evaluate the hazards present and to create effective safety measures. Specifically, there was a lack of strategies to prevent access to dangerous machine parts and an absence of protocols to halt machine movement before personnel entered hazardous areas. The investigation also revealed shortcomings in the training and supervisory measures provided to employees, which did not ensure the safe operation of equipment.

Despite improvements in health and safety protocols over recent years, the sawmilling sector continues to be classified as one of higher risk. Statistics indicate that the rate of major injuries in this industry is over two and a half times greater than in general manufacturing. Machinery-related mishaps are amongst the leading causes of injuries within the field, with inadequate lock-out procedures during mechanised operations posing ongoing challenges. Alarmingly, the industry on average sees one fatal accident each year.

The specific guilty plea from E.T.C. Sawmills was for violating section 2(1) of the Health and Safety at Work etc. Act 1974, which mandates that employers ensure, as far as reasonably practicable, the health, safety, and welfare of employees at work. The court also directed the company to pay costs amounting to £7,395.51.

HSE Inspector Keeley Eves commented on the seriousness of the situation, stating, “E.T.C Sawmills is one of the largest manufacturers of softwoods for the fencing and pallet industries in England. The life-changing injuries sustained by Mr Stubbs could easily have been prevented if the company had acted to identify and manage the risks involved, put a safe system of work in place and ensured that employees were appropriately trained and supervised.”

The prosecution, led by HSE senior enforcement lawyer Nathan Cook along with paralegal Sarah Thomas, highlights the critical need for rigorous compliance with health and safety regulations, particularly in high-risk industries such as sawmilling.

To support safer working environments, the HSE has made available considerable guidance aimed at the sawmilling sector. This guidance focuses on enhancing safety measures to protect employees from Industry-specific risks and can be accessed through the HSE’s official resources.

The implications of Mr Stubbs’ injuries extend beyond just personal impact, raising broader concerns regarding workplace safety culture within the industry. Experts note that even with advancements in safety protocol, the persistent occurrence of serious injuries indicates a pressing need for an overhaul of safety practices, along with greater education and awareness initiatives targeting employees at all levels.

The necessity of continuous education and training for workers in hazardous environments remains critical. Regular safety drills, thorough instruction, and active engagement in safety processes can significantly mitigate the risks associated with machinery operation. Industry leaders advocate for a proactive approach in fostering a culture of safety, where employee well-being is at the forefront.

Stakeholders have noted the legal and ethical implications of neglecting workplace safety, urging companies to prioritise effective risk assessment and management systems. By embracing a more diligent approach to health and safety compliance, firms can protect their workforce and ensure adherence to statutory requirements.

In conclusion, the case against E.T.C. Sawmills serves as a stark reminder of the need for stringent safety measures in settings where heavy machinery is in operation. With continuous monitoring and improvement in safety standards, the sawmilling sector can work towards a safer future for its employees, ultimately reducing the incidence of workplace injuries and fatalities. The HSE remains committed to promoting safety in various industries, continuing efforts to educate and enforce compliance to help safeguard workers throughout the UK.

Our Thoughts

E.T.C. Sawmills Limited’s failure to prevent access to dangerous moving parts and to implement effective risk assessments directly contributed to the life-changing injuries sustained by Robert Stubbs. To avoid such incidents, the company could have established robust safety protocols, including ensuring that all machinery had proper lock-out/tag-out procedures to prevent accidental activation during maintenance or jam clearance.

Key lessons include the necessity for comprehensive risk assessments, implementation of safe systems of work, and continuous training and supervision of employees regarding the operation of machinery. The HSE’s guidance specific to the sawmilling industry should be strictly followed to address inherent risks.

The company breached section 2(1) of the Health and Safety at Work etc. Act 1974, which mandates employers to ensure the health and safety of their employees by taking necessary precautions. To prevent similar incidents in the future, continuous training, regular audits of safety practices, and the adoption of technology to minimize workers’ exposure to hazards should be prioritised.