Story Highlights

– Employee injured by unguarded tube polishing machine.

– Severe injuries included finger amputation and crushing.

– Company fined £24,000 for safety regulation breach.

– HSE emphasized need for proper machinery guarding.

– Incident deemed entirely preventable by HSE inspector.

Full Story

A metal polishing business based in Oldbury has been penalised following a safety incident that left an employee with serious injuries, including the amputation of a finger. The case, which has drawn attention to workplace safety standards, highlights serious lapses in equipment management.

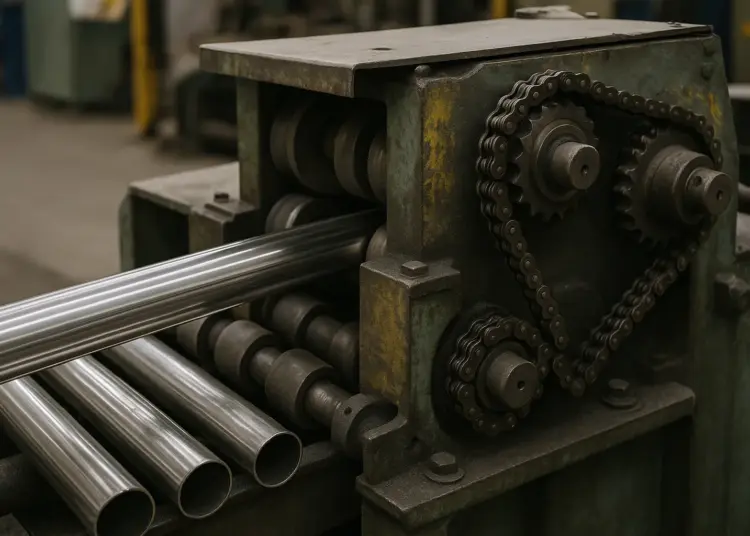

On 8 July 2024, Nathan Watkins, an employee at FMP West Midlands Limited, was loading a tube polishing machine when the accident occurred. The machinery in question was equipped with faulty rollers, which compelled Mr Watkins to lean over it to adjust the metal tubes. In the process, his left hand became caught in the unguarded components of the machine, particularly the rotating cogs and chains.

As a result of this horrific incident, Mr Watkins suffered severe injuries: his left ring finger was amputated to the first knuckle, his middle finger sustained crushing injuries that necessitated a metal rod insertion, and his index finger was also severely impacted and required multiple surgeries. Despite his efforts to recover, the 35-year-old has undergone eight medical procedures and is anticipated to need more in the future. Since the day of the incident, he has been unable to return to his job.

“I have gained some strength back in my hand, but it is very tender and painful,” Mr Watkins described, emphasising the long-term effects of the accident on his daily life and work capabilities.

In the wake of the incident, the Health and Safety Executive (HSE) conducted an investigation and found that FMP West Midlands Limited had inadequately safeguarded their machinery. The company failed to prevent access to dangerous parts, an essential element of workplace safety stipulated under the Provision and Use of Work Equipment Regulations 1998 (PUWER).

PUWER regulations mandate that dangerous machinery parts must be physically enclosed and properly secured to prevent accidental access. Specific guidance indicates that any guarding should not only be installed but should also remain firmly in place to minimise risk to workers.

On 5 December at Birmingham Magistrates’ Court, FMP West Midlands Limited, located on Rood End Road in Oldbury, admitted to violating regulation 11(1) of the PUWER. The court imposed a fine of £24,000 on the company, which also included a £2,000 victim surcharge and additional costs of £4,073.10.

HSE inspector Taila Phelan remarked on the preventable nature of the incident, stating, “This incident was entirely preventable. There is clear and long-standing guidance on machinery guarding to prevent access to dangerous parts. The failure to maintain proper guarding standards is not acceptable and too many workers are still being injured by machinery due to employers not taking the necessary steps to protect their employees.” Phelan further elaborated on the case by stating, “The tube polishing machine was not up to safety standards. Had FMP West Midlands Limited installed suitable guarding, this life-changing injury would not have occurred.”

The prosecution was pursued by HSE enforcement lawyer Edward Parton and paralegal officer Jorge Kemp, highlighting the regulatory body’s commitment to enforcing health and safety compliance across the industrial sector.

The HSE serves as the national regulator in the UK for workplace health and safety, focusing on protecting both individuals and communities by promoting safer working conditions. Their ongoing efforts intend to reinforce the importance of regulations designed to keep workers safe, particularly in high-risk environments where machinery is involved.

Recent statistics from the HSE indicate a continuing trend of workplace injuries related to inadequate safety measures. Given this context, incidents like that of Mr Watkins shine a light on the pressing need for strict adherence to safety protocols, with employers urged to prioritise preventive maintenance and proper training for their staff.

Furthermore, with recent advancements in machinery safety technology, there are ample resources and practices available to businesses to enhance equipment safety. HSE continues to provide guidance on these measures, including the Approved Code of Practice and Safety Guidelines available through their official website, which emphasise the necessity of comprehensive risk assessments and equipment inspections.

Public interest in workplace safety has been amplified amid ongoing discussions about health regulations in various industries, advocating for more stringent enforcement and better investment in employee welfare. This case serves as a reminder that complacency regarding safety standards can lead to devastating consequences for individuals and their families.

As the story of Nathan Watkins illustrates, the repercussions of workplace accidents extend beyond immediate physical injuries, impacting the victim’s quality of life and ability to earn a livelihood. The penalties imposed on FMP West Midlands Limited underscore the accountability of businesses in ensuring a safe working environment for their employees.

As industry reference points, both HSE and organisations across various sectors must continue advocating for robust safety standards, fostering a culture of proactive health and safety management rather than reactionary approaches after incidents occur. The message remains clear: preventing workplace injuries requires continuous commitment to safety from all involved.

Our Thoughts

FMP West Midlands Limited’s incident involving unguarded machinery highlights significant failures in health and safety practices. To prevent such occurrences, the company should have implemented comprehensive safety measures, particularly the installation of fixed guards to prevent access to dangerous parts of the tube polishing machine, as mandated by the Provision and Use of Work Equipment Regulations 1998 (PUWER). The investigation revealed a breach of regulation 11(1), which emphasizes the necessity of guarding dangerous machinery.

Key lessons include the imperative of regular equipment maintenance and adherence to safety standards. By failing to maintain proper guarding and not ensuring the machine was safe for use, the company neglected their duty of care under the Health and Safety at Work Act 1974.

To avoid similar incidents, organisations must prioritise effective risk assessments, ensure employee training on machinery use, and foster a culture of safety compliance. This incident serves as a cautionary tale that underscores the legal and ethical obligations businesses have to protect their workers from preventable hazards.